Project Info

Project Summary

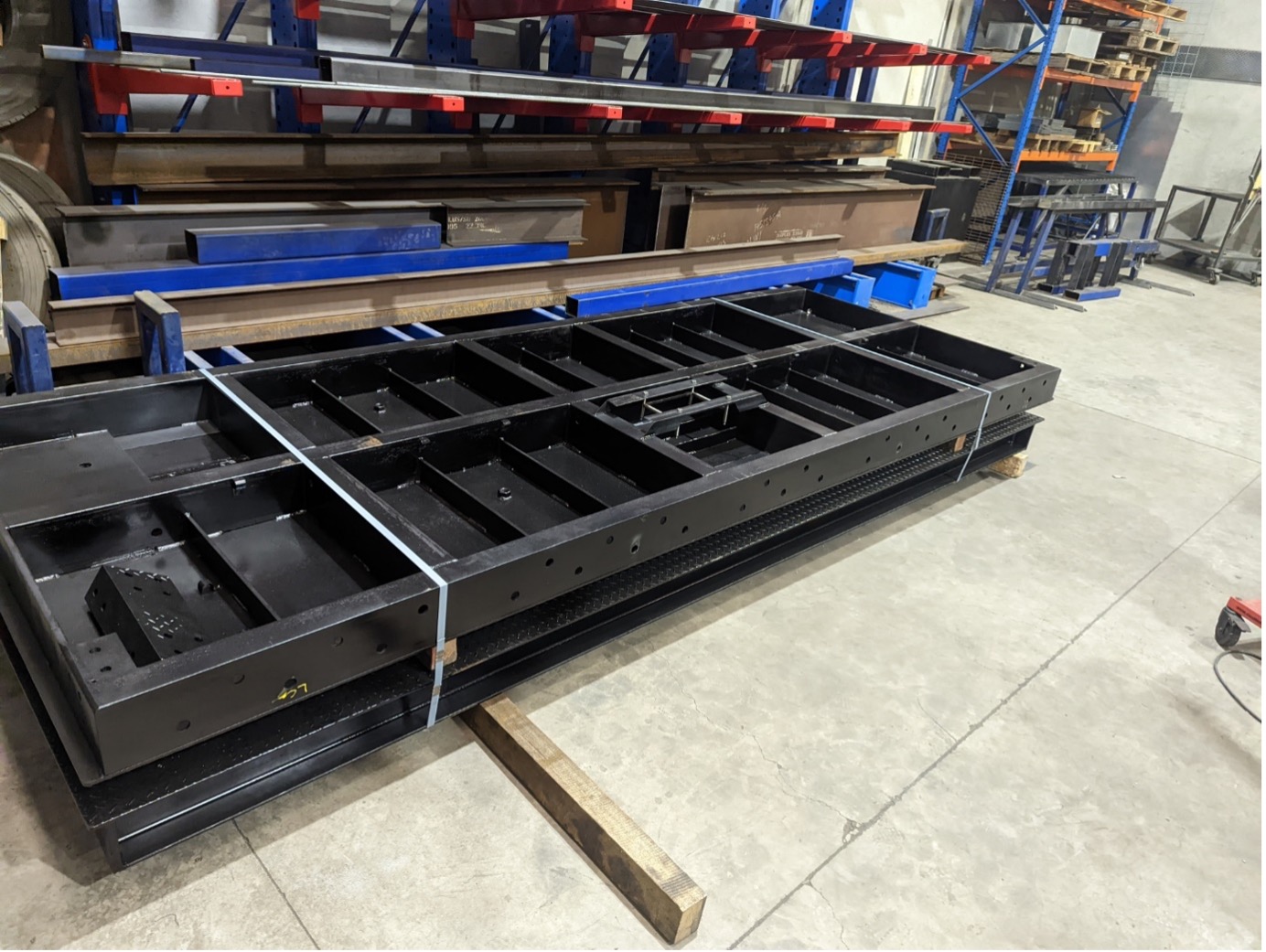

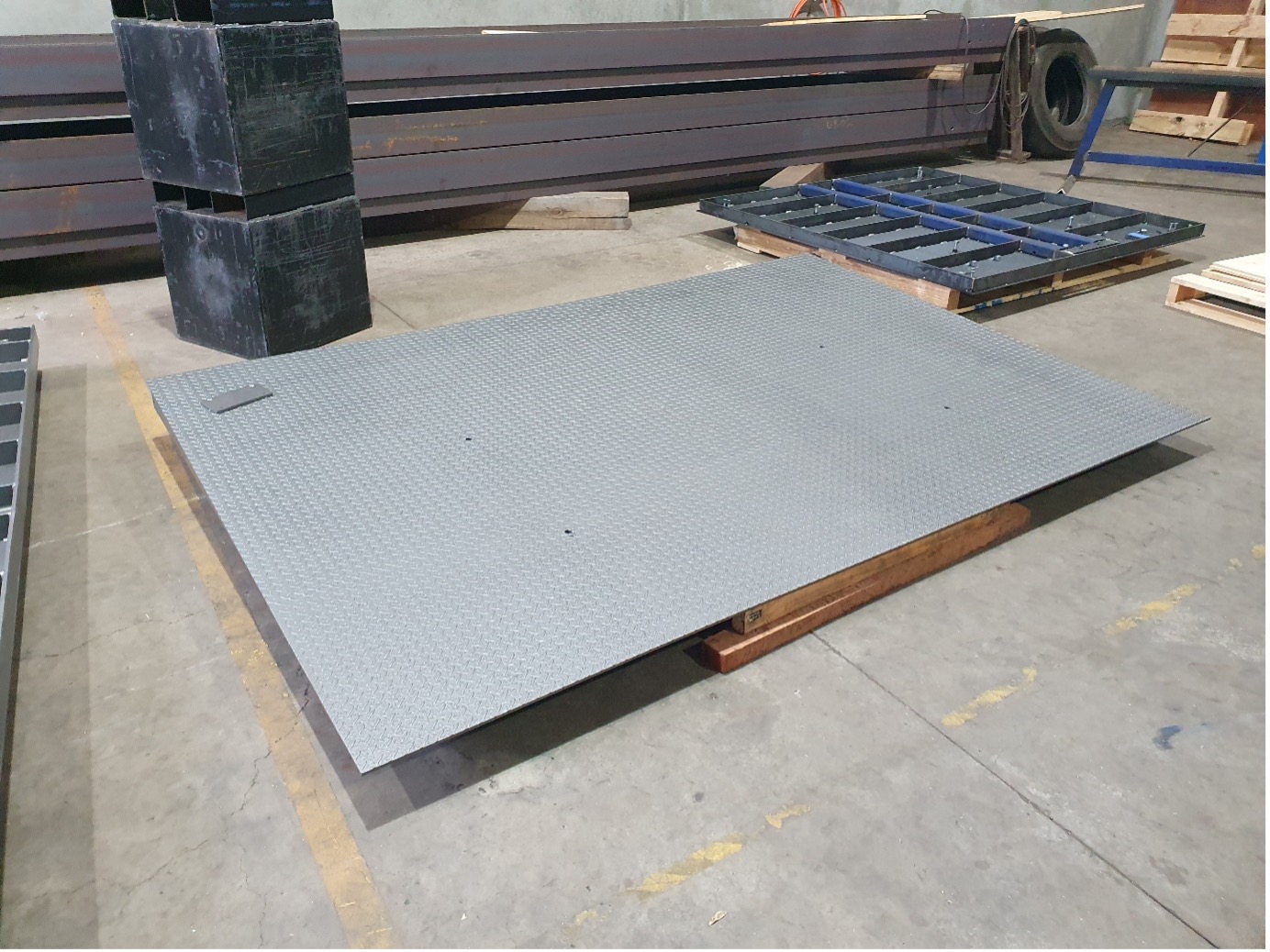

NWI Fabrication successfully delivered a custom structural steel solution for Berendsen Fluid Power, aimed at supporting a 1.6-ton gantry crane. This project required not only the design and fabrication of a robust steel structure but also the seamless coordination of delivery, installation, and testing. By working closely with Berendsen Fluid Power from the initial stages, NWI provided a comprehensive end-to-end solution that met the project’s technical demands while ensuring safety and structural integrity.

Gallery

Challenges & Solutions

Challenge: Ensuring the structural support system would integrate with existing site conditions while meeting the load requirements of the gantry crane.

Solution: Multiple onsite inspections and close collaboration with Berendsen Fluid Power during the design phase allowed NWI to develop a custom solution that addressed all site-specific challenges.

Challenge: Coordinating the delivery and installation of large, heavy components in a busy operational facility.

Solution: NWI managed the entire process, including delivery logistics and crane operation, ensuring a smooth installation with minimal disruption to the client’s operations.

Benefits

NWI Fabrication delivered a robust, custom structural steel solution that successfully supported the installation of a 1.6-ton gantry crane for Berendsen Fluid Power. The project was completed on time and in full compliance with all relevant safety and structural standards.

Through early-stage collaboration, meticulous planning, and high-quality fabrication, NWI ensured that Berendsen’s operational needs were met with minimal disruption and maximum efficiency.

By providing a full end-to-end solution—from design and fabrication to site delivery, crane operation, and weld testing—NWI demonstrated its expertise in handling complex structural projects and ensuring that all aspects were managed with precision.

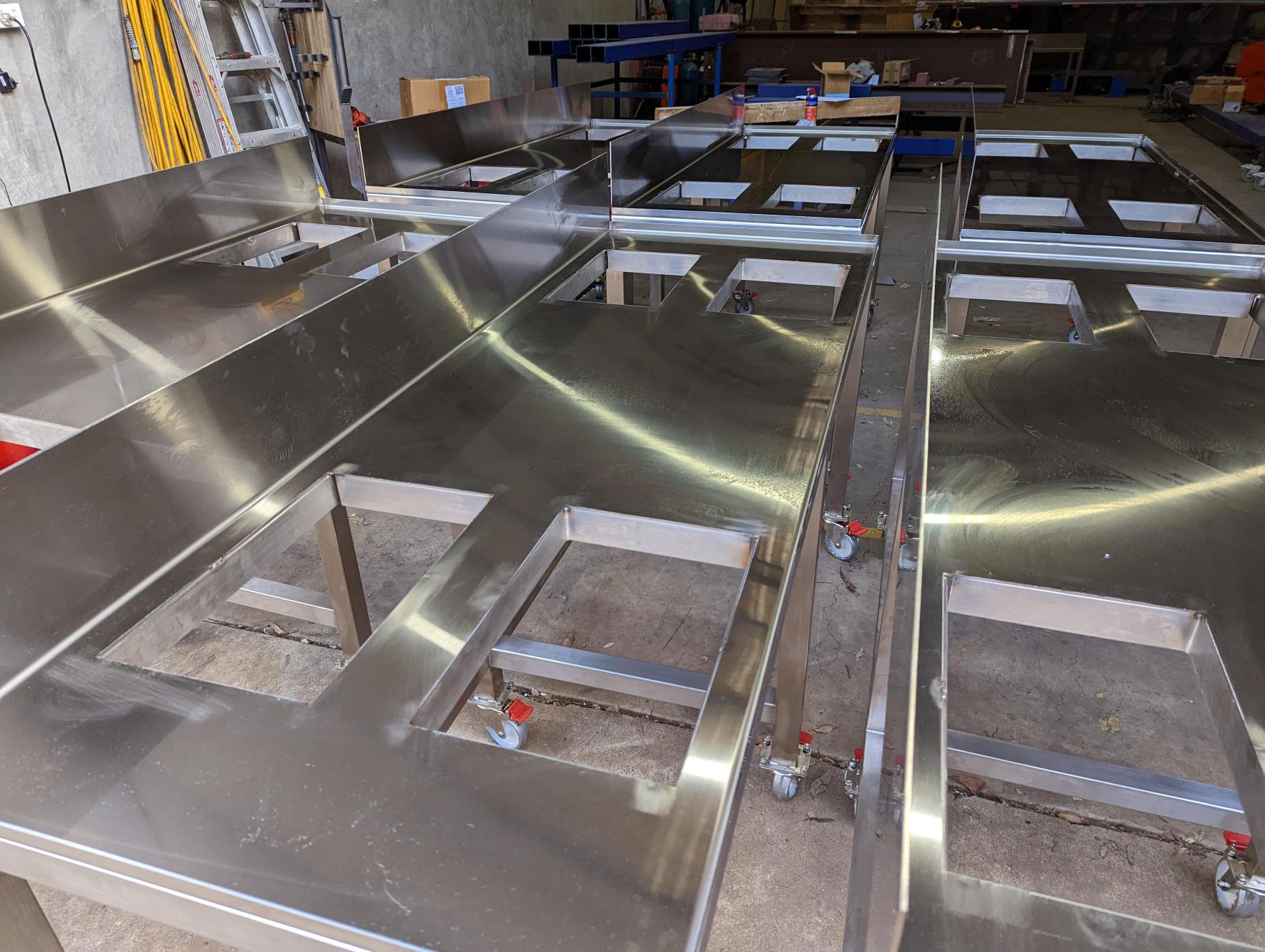

Other Projects

East Rocking Ham Waste to Energy

Northline Logistics

Menzies Aviation Platform Scale and Ramps

Rosebury Engine Yards

Lynas Corporation

Berendsen Fluid Power

Consolidated Property Services

Big Screen Video

Contact Us